CMM Inspection

Part Scanning

Hydraulic Pressure Test

Pneumatic Pressure test

Flow Testing

Clean and Flush certified

Component Assembly

AQI is dedicated to meeting or exceeding customer quality requirements, on time delivery and providing great value. Our culture centers around providing our Associates with an environment where training, continuous improvement, respect and sustainability our core values.

Utilizing our ERP system, AQI has visibility on all material and service items. Procurement and Manufacturing personnel are in constant contact making sure that material and services meet our needs.

L. Stephen Prout, President

We understand your needs and how important service is to you. Earning your trust through high quality and on-time deliveries is how we operate.

AQI operates in a 74,000 sq. ft. building with capacity to handle your requirements. We have been approved for another 25,000 sq. ft. building as soon as customer demand needs it.

Associates highly skilled in engineering, quality, 5 axes machining, assembly. With over 65 years in business, our talent resides in our people.

Business groups, AlphaQ and Glastonbury Southern Gage with manufacturing plants located in both Colchester, CT and Erin, Tennessee

Years of experience manufacturing aerospace products and world class gages.

Machining a part to close tolerances doesn't mean much if you can't check it. At AlphaQ we utilize the latest inspection technologies to ensure we are supplying only the best quality. Our processes are rigorous, thorough and are performed by highly qualified inspectors.

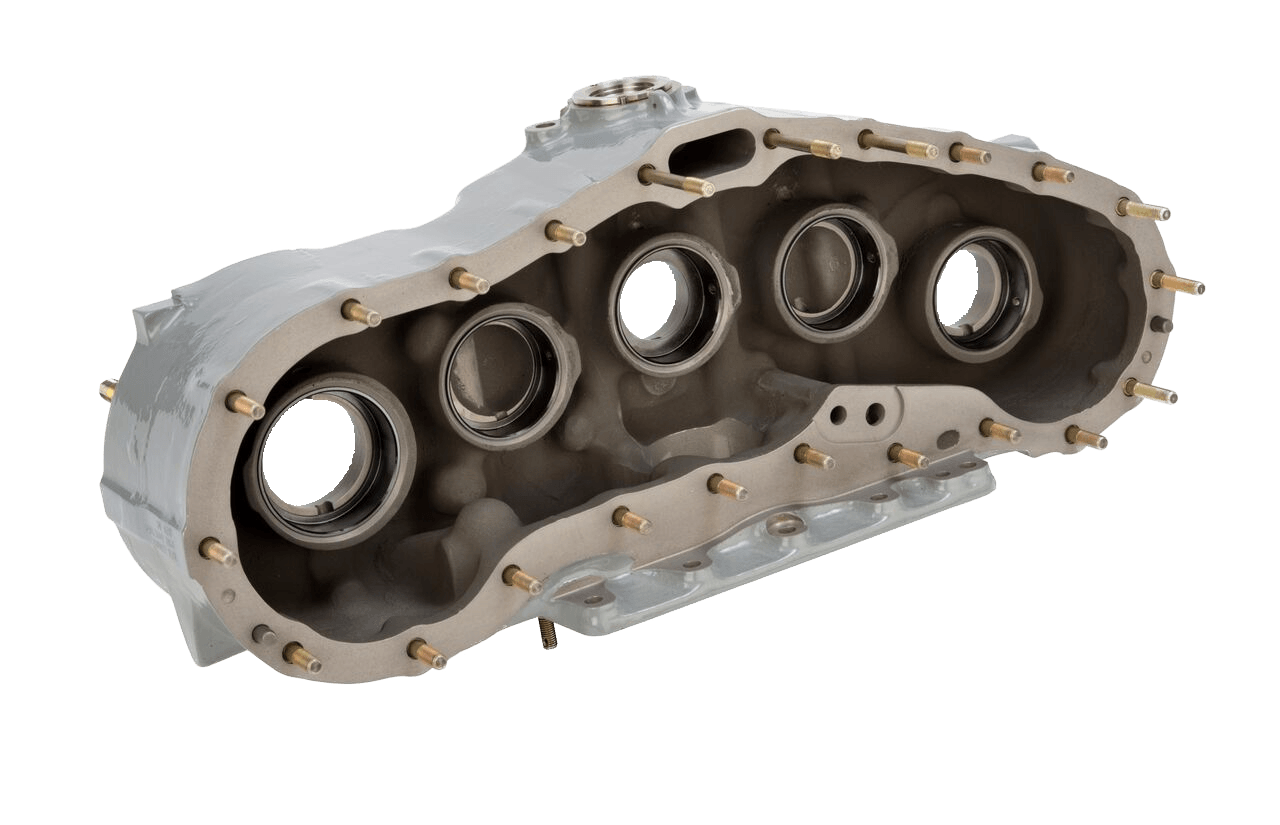

Alpha Q is a Tier 1 supplier to OEMs such as Sikorsky, Rolls Royce, and Honeywell. Focused on the aerospace, commercial, and military industries, We manufacture Complex Aerospace Jet Engine Components & Provide CNC Machining, Concurrent Engineering & Assembly and Testing Services. Our goal is to maximize machinability, while maintaining a quality product. We are ISO 9001 and AS9100 certified. Using the latest state-of-the-art equipment and manufacturing practices including lean manufacturing techniques (Regular Kaizen events. Employing 6s methodology) we have built our reputation on providing on-time delivery and exceptional quality for all the products and services we sell.

Please feel free to review our Quality policy

Click on the link below to view/download our terms & conditions

Please feel free to review/download our Quality Requirements for Purchasing

Please feel free to view/download our accreditations here

CMM Inspection

Part Scanning

Hydraulic Pressure Test

Pneumatic Pressure test

Flow Testing

Clean and Flush certified

Component Assembly

AQI has invested in the latest technology: full five axis Mill/Turn with Palletech System, machine probing, CMM scanning, Blue Light Scanning and the latest manufacturing software. This provides unparalleled manufacturing capability and the most cost-effective solution.

AQI has a talented Engineering Staff utilizing the latest in programming software and modeling. Using Lean Manufacturing principles, we always look for the most cost-effective method to process the components. This includes special tooling to produce multiple features in one pass, machine probing, multipurpose fixturing and the latest in cutting tools. We are comfortable working with customer computer models.

Some of our capabilities:

Rich Hurley, COO & General Manager